Artificial Christmas Tree Automation Equipment

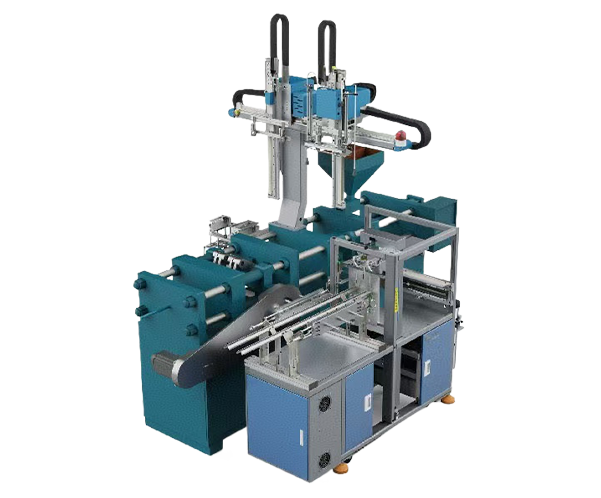

Automatic PE Branch Injection Molding and Yellow Core-line PaintingSystem

Automatic PE Branch Injection Molding and Yellow Core-line PaintingSystem

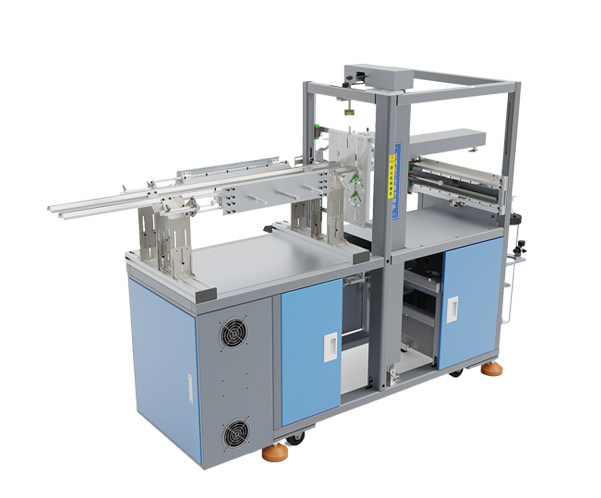

Unit Style PE Branch Yellow Core-line Painting Machine

Used in conjunction with injection molding robots to achieve integrated production of pine branch injection molding and yellow core production.

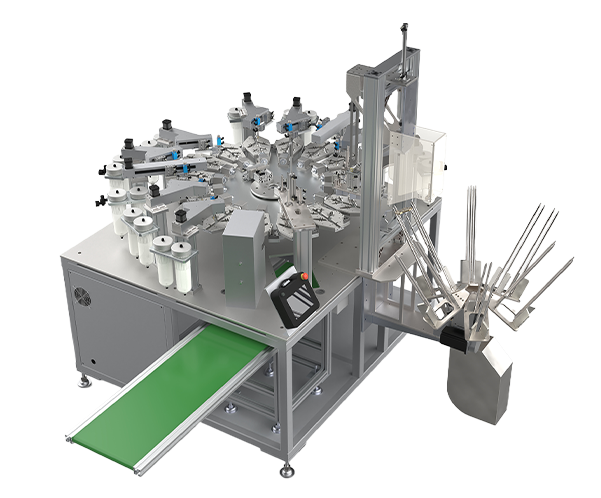

Rotary Style Automatic Yellow Core-line Painting Machine

Highly automated: The equipment achieves semi-automatic feeding of Christmas tree PE leaves, fully automatic discharging, automatic yellow core punching, automatic wave pattern pressing, and automatic product flipping.

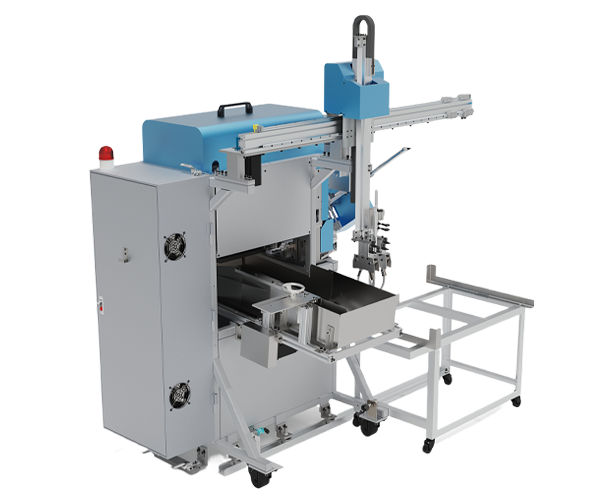

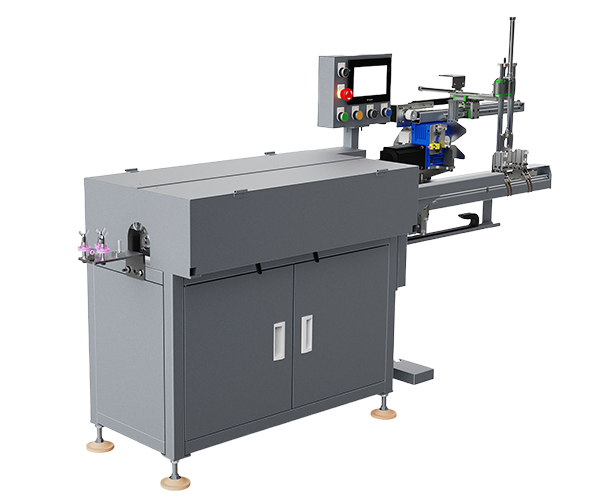

Automatic PVC Branches Cutting Machine

High-precision sensors detect the servo cutter, ensuring stable quality. A single shift saves approximately 60,000 liters of high-pressure air (compared to semi-automatic systems).

Semi-Automatic Branch Binding Machine

High safety: Automatic sorting and conveying of iron wires from 6 to 27 inches, with the mechanism set inside the chassis, preventing injuries caused by the iron wires popping out due to poor bending during transportation.