Semi-Automatic Branch Binding Machine

Key words:Automation Equipment

Classification:

Product Description

Product Features:

1. High safety: 6-27 inch iron wire is automatically sorted and conveyed, with the mechanism set inside the machine case, preventing injuries caused by improper bending of the iron wire during transport.

2. Strong scalability: Modular design allows for connection with sleeve modules, bending hook modules, and fully automatic strip feeding machines.

3. Convenient operation: The touch screen combined with physical buttons makes operation simpler. To start production, you only need to press the physical button to complete actions such as: start, reset, rework. The touch screen can be used for parameter settings and can directly call historical data.

4. More efficient: The main machine's binding feed uses a double-clamp structure, with the iron wire fed from the back, eliminating the need to wait for the clamps to return after binding.

| Key Parameters | Model |

| LH-BZJ-A27-W① | |

| Maximum length of the machine body | 655mm |

| Maximum width of the machine body | 655mm |

| Maximum height of the machine body | 1420mm |

| Applicable iron wire length size | 4 inches - 26 inches (100mm - 650mm) |

| Applicable iron wire gauge | 12 gauge - 6 gauge (2.8mm - 5mm) |

| Binding efficiency | Approximately 1500 leaves/hour (pure PVC) |

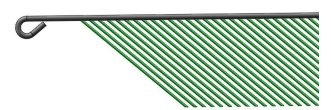

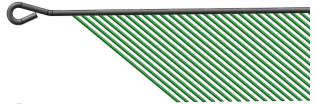

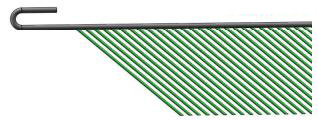

Bending hook type

Common hook shapes include the above 5 types, with inner diameters of 6mm or 8mm available. ① is the conventional hook shape, which our bending hook mechanism can produce directly, while shapes ②, ③, ④, and ⑤ require additional mechanisms to bend.

①9-shaped hook

②9-shaped hook + bending

③Reverse 9-shaped hook

④Reverse U-shaped hook

⑤7-shaped hook

More products

Project online consultation

If you have found your desired products or want to design your exclusive products, please feel free to contact, we are here for you 24/7.